- PRODUCT SPECIFICATIONS

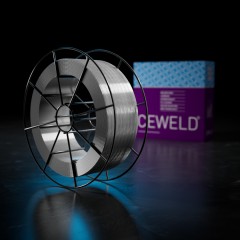

- PACKAGING

CEWELD® Alloy 263 is developped for aircraft turbine engine and industrial turbine applications. These include low-temperature combustors, transition liners, and some ring components.

CEWELD® Alloy 263 is developped for aircraft turbine engine and industrial turbine applications. These include low-temperature combustors, transition liners, and some ring components.

CEWELD® Alloy 263 should be used used for applications up to about 1650°F (900°C). Its oxidation resistance is comparable to that for other gamma-prime-strengthened superalloys. CEWELD® Alloy 263 is an age-hardenable nickel-cobalt-chromium-molybdenum alloy designed specifically to combine good age-hardened strength properties with excellent fabrication characteristics in the annealed condition. CEWELD® Alloy 263 exhibits excellent intermediate temperature tensile ductility, and is not normally subject to strain age cracking problems common for gamma prime strengthened alloys.

NIckel based alloys with simmilar composition as Nimonic 263

| Heat Treatment |

RP0,2 (MPa) |

Rm (MPa) |

A5 (%) |

Hardness |

|---|---|---|---|---|

| As Welded | 900 | HRc |

| Packaging | KG/unit | EanCode |

|---|---|---|

| BS-300 | 13,6 | 8720663419798 |

| Packaging | KG/unit | EanCode |

|---|---|---|

| BS-300 | 13,6 | 8720663419804 |